The Only Guide to Steel Road Plates

The Only Guide to Steel Road Plates

Blog Article

Steel Road Plates for Dummies

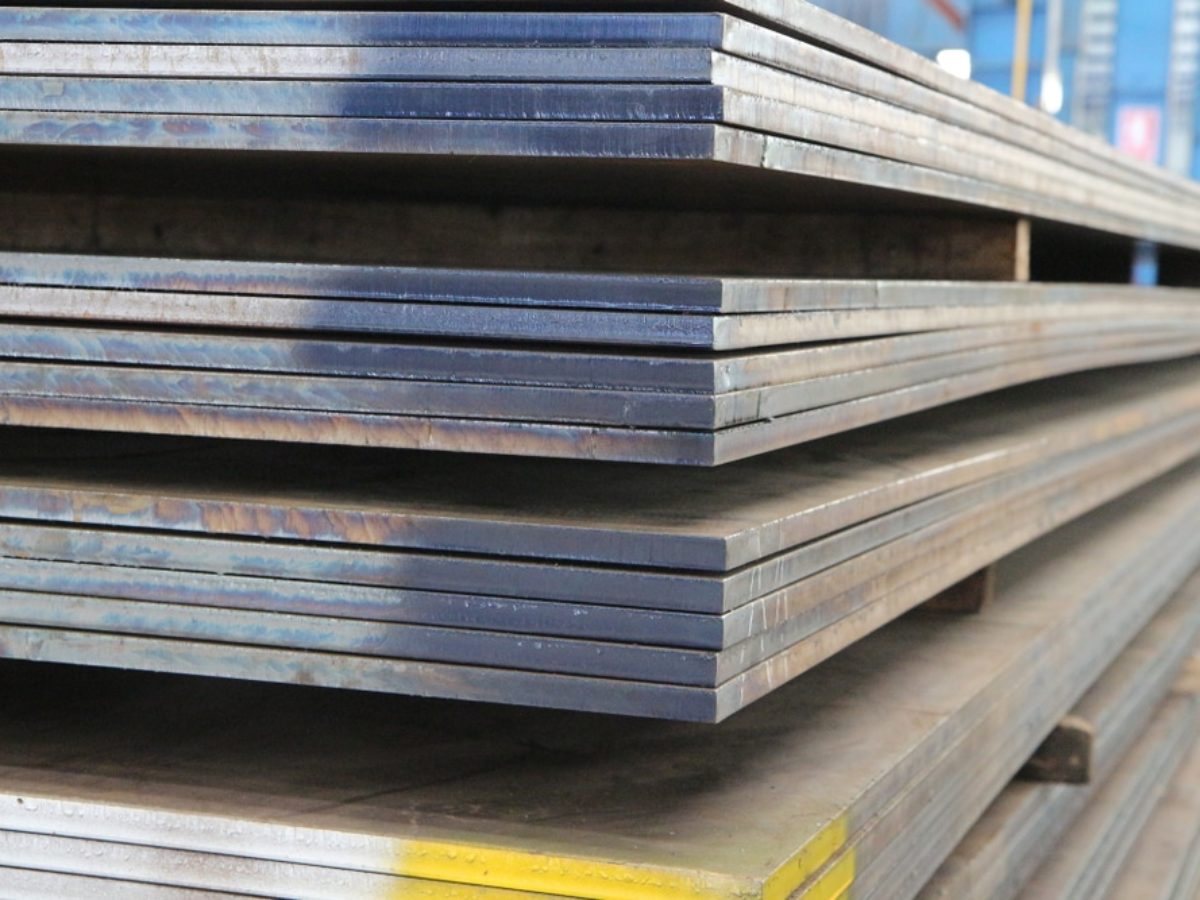

Steel plates are supply a good, temporary service for covering harmful holes on a building website. These sturdy, durable plates enable roadways to go back to service to ensure that construction can continue. Right here we discover the layout information and ideal practice installation advice. These plates can be utilized to ensure that roadways can still be used whilst various other phases of job proceed.

They provide a suitable concession for keeping lanes, whilst work proceeds overnight and at weekends. They are typically seen when excavations have begun as a very early stage of building and construction or fixing tasks. These plates are created to withstand sturdy use on active roads. They include an akti-skid coating and are available in a number of colour surfaces - Steel road plates.

The weights begin from roughly 300kg and conventional road plates have a density of either inch or inch. The capability to be bolted to the road.

The 2-Minute Rule for Steel Road Plates

Hinged versions for quick accessibility to the excavation or regular gain access to, e.g. driveways. Compound plates, which can fit different lengths of trench. For this factor, they ought to be set up using a forklift or crane.

Look for variation by web traffic filling from the outset plates must constantly stand up to displacement. Check that home plates do not provide a danger to any kind of sort of roadway individual and can be used by all road customers and automobile types, consisting of pedestrians, bikers and motorcyclists. Develop a regular examination and upkeep to ensure that efficiency remains secure and optimum.

Deal with the plates properly at all times. Mechanical training ensures that the plates are installed accurately and safely.

If a ramp is developed by the road layers, after that alerting indications for pedestrian and roadway individuals are required. Always a conduct complete site study, and take the specialist guidance of an architectural designer.

The 3-Minute Rule for Steel Road Plates

In order to enhance security, there are a number of criteria and industry papers leading their use in building and construction job areas. Steel plates should be fixed in area to avoid motion.

Facts About Steel Road Plates Revealed

In enhancement to being strongly touching the pavement, they ought to be either pinned, recessed right into the sidewalk, or protected with asphalt wedges around the boundary. Pinning into the pavement includes driving pins into the sidewalks along the sides of the steel plates to stop activity. Recessing includes eliminating the location where the steel plate will certainly be placed.

This causes the steel plate being flush with the pavement. In enhancement, when numerous steel plates are used and butt approximately each other, they must be welded with each other at the longitudinal joints. Steel plates can be really unsafe, specifically when they are damp, unless they have an anti-skid covering applied.

Treatment steel layers with a product that enhances friction aids motorcyclists and bicyclists keep control, particularly in damp weather. Conditions which decrease sidewalk friction in job zones are of specific worry to motorcyclists and bikes. A typical threat in steel plate setups occurs when the user stops working to build appropriately tapered ramps from the highway to the edges of the steel plate( s).

The Steel Road Plates Statements

It presents a significant risk to motorcyclists and bicyclists who can easily shed control when they speak to the abrupt/steep tapered ramp and the steel plate. Effectively conical ramps permit users to safely go across over the steel plates. Tapers for steel plates are generally built of asphalt. The taper lengths differ from State to State and generally array from 20 to 1 to 120 to 1 (Steel road Steel road plates plates).

Department of Transportation's Federal Highway Administration (FHWA) requires that transverse sidewalk joints, which lead to a bump, have to be tapered at 60 to 1 (5 feet straight for every 1 inch of upright elevation difference). Select the appropriate size. Ensure adequate overlap. Generally, steel plates need to expand at least one foot past the pavement opening onto company ground.

Some Ideas on Steel Road Plates You Need To Know

Welding is made use of when greater than one steel plate is made use of and they butt as much as each other. Plates should be countersunk when needed as a result of uneven streets. Plates ought to be covered with an anti-skid covering. The sides of the steel plates must be marked/painted to boost visibility. Correct development caution indicators should be used.

His history includes the construction, evaluation, read more.

These durable steel plates play an important function in boosting construction safety and security, offering momentary highways, and guaranteeing smooth procedures on various job sites. As a building and construction devices vendor, their value can not be overemphasized.

Report this page